The LNV antenna with my southwest tower (which is the transmitting vertical for 160 meters) behind it

Note 12 May 2018: I moved this antenna to a new location and made a discovery. It had been working in part due to mutual coupling with my transmitting antenna. I should have known this because when I resonated the transmitting antenna on 2200m the LNV noise floor and signal levels came up about 20 dB on that band. Similarly when I resonated the transmitting antenna on 630 meters, output of the LNV came up nearly 10 dB on that band. When I moved it away from the transmitting antenna, output on both bands dropped to within 3 dB of my receiver noise floor even with the preamp (my simple SDRs are not ultra sensitive). Another factor may have been that the new location was surrounded by trees. The antenna has been moved back to its original location. Subsequently, a new receiver allows noise from the LNV to be about 12 dB above the receiver noise floor.

During the initial phase of experimentation I had found that some of my 160 meter Beverage antennas worked reasonably well for receiving on 2200 and 630 meters. I was hearing plenty of Europeans on both bands. Obviously at these frequencies they didn’t work as Beverages. What the actual operating mode was I don’t know. There were a few problems with this arrangement, primarily that I couldn’t run LF and MF receive operations concurrently with 160 (or 80) meter DXing. That was not good!

After reading a number of blog posts and web articles about the “low noise vertical” or LNV, I decided to give it a try. VE7SL has an article on his blog with links to additional information. As is often the case I pulled ideas from several sources, then mixed and matched (and even went off on my own a bit) for my version. My LNV is a 30 foot self supporting vertical made from scrap aluminum tubing I had on hand. It starts out with 1.5 inch OD at the base and tapers to 1/2 inch at the top. The bottom foot of the vertical is slid inside a two foot piece of 1.5 inch schedule 40 PVC pipe and secured in place with set screws (bottom) and a worm clamp (top). Looking at the photo that may be confusing. The set screws (three 1/4-20 stainless tap bolts) go through the worm clamp and PVC just above the transformer box. You can see that in the photo. What is not visible is the other worm clamp securing the aluminum tubing to the top of the short PVC section. These details are unimportant. Just make sure your vertical is insulated at the base! A piece of wire hanging from a tree would no doubt work just as well, but I wanted to do mine this way.

A couple of words about the overview photo at the top of this post. First, in the thumbnail you may not be able to make out the LNV in the foreground just to the right of the tower behind it. Second, usually the yagi antennas on that tower are lined up with each other! We had a recent storm with wind gusts to 70 mph which skewed things and I haven’t been up to fix it yet. The LNV is only 40 feet from that tower which is my 160 meter transmitting vertical (shunt fed). Thanks to good band pass filters, my 2200 and 630 meter receivers don’t react at all when I transmit with 1500 watts on 160.

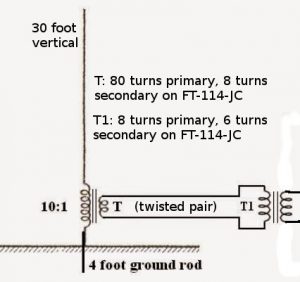

In some write ups about the LNV it is said one needs more than one ground rod for best performance. Surprisingly I am using just one four foot “ground rod” which is a section of a stainless steel mobile antenna whip which I pushed into the sandy soil by hand! I plan to try adding real ground rods later but the antenna is working with the minimal ground. As of this writing it has heard 2E0ILY nine consecutive nights on 2200 meters.

My LNV is fed with about 250 feet of WD1A twisted pair wire which is laying on the ground. This is ex military field phone wire and is practically indestructible as long as you keep water out of the ends. It has three steel and four tinned copper strands in each conductor along with incredibly tough insulation that takes a lot of abuse. Any twisted pair wire should work fine in this application.

The transformer at the antenna base is wound on a FT-114-JC core, 80 turns primary, 8 turns secondary. First, the 80 turn primary is wound directly on the core using 20 AWG enameled wire. If a non-coated core is used, it would probably be wise to wrap the core with some kind of tape before winding the primary. One end of the primary winding connects to the base of the LNV, the other end to the ground rod.

The primary was wrapped with teflon thread seal tape, then the secondary was wound over the cold (ground) end of the primary using 20 AWG solid plastic coated wire. Another layer of teflon tape keeps everything nice and tight. The secondary winding connects to the twisted pair feed line.

The finished transformer is mounted in a small plastic mini box of the type that has a rubber gasket to keep out water. The ground and antenna connections are #8-32 stainless machine screws at opposite ends of the box, while the connections for the twisted pair feed line are together on one side of the box.

Twisted pair to coax transformer for the shack end of the feed line. The RCA connector has subsequently been replaced by a BNC

At the shack end of the feed line I use another FT-114-JC core with 8 turn primary (twisted pair from the antenna), 6 turn secondary for 50 ohm coax to the receiver (or in my case two receivers via a splitter).

After using this antenna for 10 days, initial results are very promising, especially on the lower band. I am not able to listen with this and the old antenna at the same time, but I am hearing 2E0ILY on 2200 meters much more often and with stronger signals than I ever did with the short Beverage. To the west it seems about on par with the Beverage. On 630 meters I don’t think it is quite as good, but I am hearing a number of Europeans.